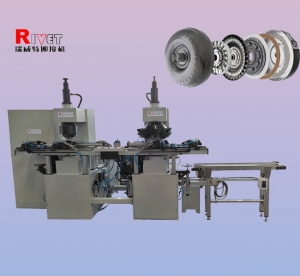

Torque converter riveting machine

Torque converter riveting machine

GMX-2(Automotive turbine production-CNC riveting machine) Torque converter riveting machine The equipment meet turbine blade claws\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\'s automatic roll riveting process.Fully automatic functions including main machine,tooling,fixture,tools,transer mechanism, hyraulic station,automatic logistics transmisson system,and control system. Technical requirement: 1.Spindle accoracy: Radial ≤0.02mm,distal runout≤0.015mm (distance from face 300mm) ,shoulder bounce ≤0.01mm; 2.Spindle speed 0~100rpm adjustable,and motor power not less than 3.5KW 3.Rolling tool\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\'s drop(rising) speed adjustable, with fast speed and working speed,fast speed forward idel,and working speed when tool/tooling approaching workpiece;fast back when return,the minimun working speed can reach 2mm/s. synchronous feed and stable. 4.Machine machine should be equipped with safety interlocking device to avoid equipment damage or personal injury caused by misoperation. 5.Machine should be equipped with an independent operation panel, which can carry out manual operation of a single device, and the operation height is in conformity with ergonomics. 6. Machine\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\'s slide rail / guide column adopts international famous brands with sufficient rigidity and precision. 7.The design of tooling should be designed for quick change. The overall switching of tooling should not exceed 30 minutes and the tool change should not exceed 3 minutes. 8.Tooling with centering function, positioning accuracy ≤0.05mm. 9.Rolling tool has a blade pre-inverting function: after the workpiece is pre- pressed, the blade is pre-prepared by using a pre-blade, and the blade is to be bent from the root after pre-falling. 10.Rolling knife adopts floating design, with certain self-adaptability, rolling

Send Enquiry

.jpg)