Rotational Molding Machines & Mould

Rotational Molding Machines & Mould

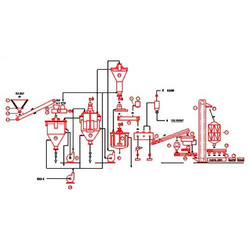

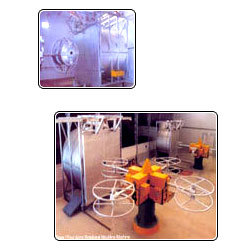

This is a three stage, pressure less, plastic molding process. In the initial stage of heating, there is a bi-axial rotation of the charged mold. Furthermore, the plastic charge in the mold gets melted and uniformly coated due to the heat transfer. The second stage involves the molten plastic charged coating of the mold to solidify and move to the cooling station. In addition to this, the mold can be cooled by using water spray and air, even when it continues rotating in its arm.

At the final stage, which is also known as load/unload stage, by opening the nut bolts or de-clamping all the clamps, the mold is opened. After removing the part from the opened mold, a new charge of material is loaded into it. Finally, the nuts and bolts or clamps are tightened to close the mold, which can then be used in next cycle. It is called as a continuous process because at the time, when the first arm goes through second stage, the second arm goes through the first stage. Also, at the same time the third arm goes through third stage and so on.

Send Enquiry