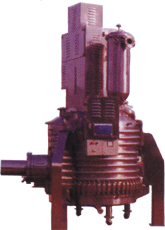

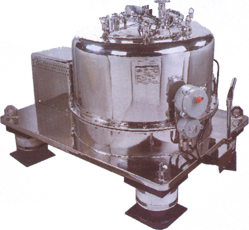

Rotary Vacuum Dryer

Rotary Vacuum Dryer

Rotary Vacuum Dryer is simple & effective method of drying wet cake, powder & even slurry. The operation is under vacuum & hence it is possible to dry heat sensitive materials at temperature well below 100c without suffering the problems associated with very long drying periods. Valuable Organic Solvents can be conveniently condensed and recovered. Labour requirement is minimum and product losses during handling are negligible provided. The agitator is usually the hallow cylinders with hollow arms this allows a considerable increase in heating surface are therby reducing the drying time. Low temperature drying under vacuum makes them more suitable for heat sensitive materials to maintain the quality. The Expensive solvents can be almost completely recover through a suitable condenser & vacuum receiver. As a heating media we can used thermic fluid, steam or hot water. When hot water is used for heating it can be electrically heated when steam is not available.

In rotary vacuum dryer which are jacketed cylindrical vessel, wet feed is charged as a batch and is subjected to indirect heating while undergoing agitation due to the action of paddle mixing. These rotary vacuum dryers have specially designed scraper blades which scrap the entire internal surface of the dryer and continuously move and rotate the material, thereby precluding the possibility of material remaining in contact with hot surfaces for protracted periods of time. The operation is normally carried out in vacuum. Recovery of solvent is possible by condensing the vapours generated during the drying operation.

Special Features of Rotary Vacuum Dryer

Granular / pasty wet materials can be handled.

Low temperature operation is possible.

Solvent recovery can be carried out

System is batch

High energy efficient

Mode of heating is indirect

Conduction drying

Closed operation

Send Enquiry