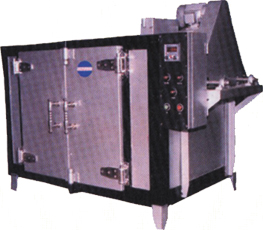

Fluid Bed Dryer

Fluid Bed Dryer

Fluid Bed Dryer offers & lucid solution to drying wet granules, crystaline or coarse materials. Fluid Bed Dryer utilizes the principle of passing the hot air a high velocity through the bed of the material to be dried. thus causing it to fluidize.

The blower situated on the exhaust side of the drye on negative pressure principle, which creates the incuced draught and sucks in the fresh air into the dryer. A steam of hot filtered air is introduced from the bottom of product container containing the wet material.

This container is provide with the air distribution plate and a dutch sieve. The air stream is passed through the bed of the material and fluidizes the product particles by creating the turbulence in the product container. Due to fluidization each particle gets surronded by hot air, which leads to quick & uniform heating and drying Filter bags provide at the top prevent escaping of partciples from the machine.

FLUID BED DRYER SALIENT FEATURES:

Short Drying Time.

Electric / Stream Heated.

Low Drying Temperature.

5 Kg to 500 Kg Batch Capacities.

Automatic Simple Operation and Control.

Pneumatic Lifting Device for product COntainer Explosion Proof Design.

All Contact Parts of SS 304/ SS 316 Quality Material.

Available Fully GMP Model.

Provided Electric Control Panel.

PLC Operation (Optional)

Send Enquiry