Grain Refiner

Grain Refiner

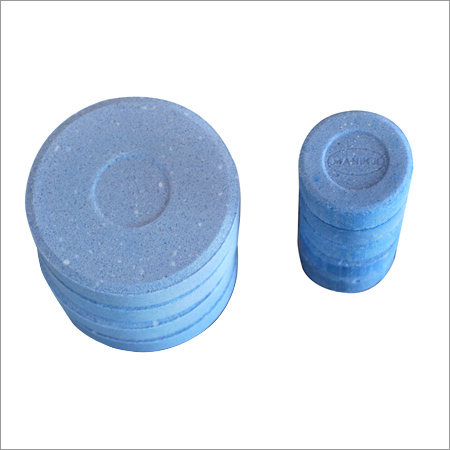

Light alloys normally form coarse and columnar crystals, which depend on pouring temperature and gradients of metal. This coarsed grain structure adversely affects heat process, impairs rolling and extrusion operations which results in low tensile strength. A simple grain refinement treatment produces a mass of minute crystals that eliminate these defects and form a fine grain structure. Advantages * Grain Refiner improves mechanical properties of all light alloys. * It ensures pressure tightness and shrinkage defects are avoided. * It reduces grain size and thereby aids feeding. * Rolled and forged products are free from cracking. * A fine grain structure improves mach inability. * Grain refiner maintains the consistency of physical properties of metal after heat treatment. Instructions When metal temperature reaches 700C, turn off the furnace and allow the temperature to increase upto 740-750C. plunge the recommended quantity of grain refiner to the bottom of the melt. When all the turbulence of grain refining operation stops, stir the metal thoroughly and perform degassing operations and finally dross off before pouring. The grain refiner is a hygroscopic material and in many foundries where it is not carefully handled or stored in open unsealed packets, it will pick up moisture. When such grain refiner is introduced in metal, it may introduce hydrogen gas into the metal. Therefore degassing after grain refining is always recommended. Packing Grain Refiner are available in the shape of 50 gms. & 250 gms. compact tablet form. The tablets are packed in 20 kgs & 40 kgs Box that is solid enough to withstand shakes and jolts of transportation.

Send Enquiry