AISI S7 HOT ROLLED TOOL STEEL BAR

Home / Products/Services / / AISI S7 HOT ROLLED TOOL STEEL BAR

AISI S7 HOT ROLLED TOOL STEEL BAR

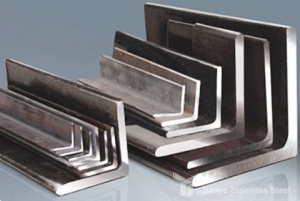

.AISI S7 HOT ROLLED TOOL STEEL BAR S7 is an air or oil hardening shock resisting (cold work) tool steel offering a unique combination of toughness and wear resistance. This material is primarily used in applications that require resistance to shock and/or impact. Chemical Composition Standard Grade Chemical composition (%) C Si Mn Cr Mo V P S AISI S7 0.45-0.55 0.20-1.00 0.20-0.90 3.00-3.50 1.30-1.80 ≤0.35 ≤0.030 ≤0.030 Available Size Hot rolled round bar: dia12mm-dia360mm Hot rolled flat bar: thickness1mm-360mm, width30mm-1020mm Available Heat Treatment Annealing/Normalizing/Hardening/Tempering/Quenching Hardness after annealing ≤HBS: 229 Hardness after cold drawn ≤HBS: 255 Preheating temperature:677°C Quenching temperature: (1)salt bath furnace: 941 °C (2)controlled atmosphere furnace: 954 °C Soaking temperature: 5-15min Cooling medium: Air cooling Tempering temperature: 204 °C Hardness after tempering≥HRC: 56 Characteristics 1. Good resistance to softening at moderately high temperatures 2. Good deformation resistance 3. S7 tool steel can be used successfully for both cold and hot work Application Blanking Dies, Brake Dies, Chisels, Die Casting Dies, Forming Dies, Gripper Dies, cold and warm header dies, shears, compression dies, hobbed dies, high hardness plastic molds, zinc die casting dies, etc. Delivery Condition Hot rolled, black surface/ turned surface with customers’ required heat treatment.

Send EnquiryRelated Products

Products / Services

- Tin Mill Black Plate / Tmbp

- Mr Or Spcc Tfs

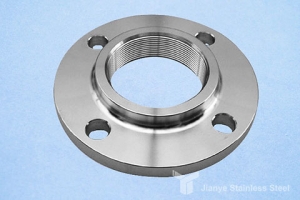

- 304 Stainless Steel Flange

- Tp304l Stainless Steel Seamless Pipe

- 304 Stainless Steel Seamless Pipe

- 316 Stainless Steel Industrial Pipe

- S31803 Stainless Steel Duplex Seamless Tube

- Astm A53 Seamless Carbon Steel Pipe

- 316 2b Stainless Steel Sheet

- Astm A179 Seamless Steel Pipe

- Tp304l Stainless Steel Tee

- 316l Stainless Steel Welded Elbow

- Tp304 Stainless Steel Seamless Elbow

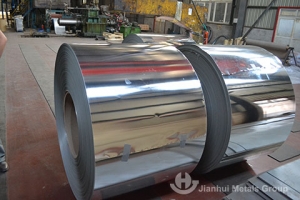

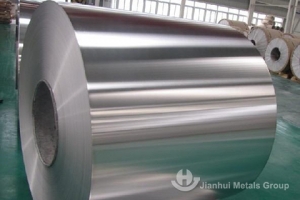

- 316l Stainless Steel Coil

- 201 Stainless Steel Coil

- 430 Ba Stainless Steel Sheet

- Stainless Steel Coil

- Tin Mill Black Plate / Tmbp

- Printing Tinplate

- Printing Tinplate

- Aisi 4140 Alloy Steel Bar

- Aisi 4340 Alloy Steel Bar

- Sae 1045 Carbon Steel Bar

- Sae 1020 Carbon Steel Bar

- S355jr Carbon Steel Bar

- S355jr Carbon Steel Bar

- Aisi 8620 Alloy Steel Bar

- Aisi 5120 Alloy Steel Bar

- Aisi 5140 Alloy Steel Bar

- 304l Cold Rolled Stainless Steel Coil

- View All

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)