AISI 4140/ JIS SCM440/ DIN 42CrMo4 HOT ROLLED ALLOY STEEL BAR

Home / Products/Services / / AISI 4140/ JIS SCM440/ DIN 42CrMo4 HOT ROLLED ALLOY STEEL BAR

AISI 4140/ JIS SCM440/ DIN 42CrMo4 HOT ROLLED ALLOY STEEL BAR

AISI 4140/ JIS SCM440/ DIN 42CrMo4 HOT ROLLED ALLOY STEEL BAR 4140/ SCM440/ 42CrMo4(1.7225) alloy steel bar is a medium carbon, chromium-molybdenum, through-hardening alloy steel that has a good hardenability with high strength and toughness as well as good fatigue and impact resistance after heat treating. Similar Grades Standard Grade Chemical composition (%) C Si Mn Cr Mo P S GB 42CrMo 0.38-0.45 0.17-0.37 0.50-0.80 0.90-1.20 0.15-0.25 ≤0.035 ≤0.035 AISI 4140 0.38-0.43 0.15-0.35 0.75-1.00 0.80-1.10 0.15-0.25 ≤0.035 ≤0.040 JIS SCM440 0.38-0.43 0.15-0.35 0.60-0.90 0.90-1.20 0.15-0.30 ≤0.030 ≤0.030 DIN 42CrMo4/ 1.7225 0.38-0.45 ≤0.40 0.60-0.90 0.90-1.20 0.15-0.30 ≤0.025 ≤0.035 Available Size Hot rolled round bar: dia16mm-dia310mm Hot rolled flat bar: thickness5mm-30mm, width50mm-130mm Hot rolled square bar: 16mm*16mm-100mm*100mm Available Heat Treatment Annealing/ Normalizing/ Hardening/ Tempering/ Quenching Hot working temperature ℃: 1050-850 Annealing temperature ℃: 680-720 Normalizing temperature ℃: 840-880 Quenching temperature ℃: 820-850 water, 830-860 oil Tempering temperature ℃: 540-680 Characteristics good overall combinations of strength, toughness, wear resistance and fatigue strength. Application Typical applications for 4140 HR bar are sprockets, bolts, chain pins, drill collars, universal joints, highly stressed parts or parts subject to severe wear. Delivery Condition Hot rolled, black surface/brigth surface with customers’ required heat treatment.

Send EnquiryRelated Products

Products / Services

- Tin Mill Black Plate / Tmbp

- Mr Or Spcc Tfs

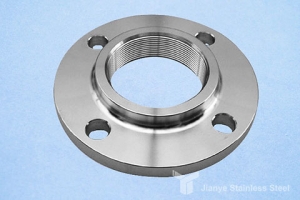

- 304 Stainless Steel Flange

- Tp304l Stainless Steel Seamless Pipe

- 304 Stainless Steel Seamless Pipe

- 316 Stainless Steel Industrial Pipe

- S31803 Stainless Steel Duplex Seamless Tube

- Astm A53 Seamless Carbon Steel Pipe

- 316 2b Stainless Steel Sheet

- Astm A179 Seamless Steel Pipe

- Tp304l Stainless Steel Tee

- 316l Stainless Steel Welded Elbow

- Tp304 Stainless Steel Seamless Elbow

- 316l Stainless Steel Coil

- 201 Stainless Steel Coil

- 430 Ba Stainless Steel Sheet

- Stainless Steel Coil

- Tin Mill Black Plate / Tmbp

- Printing Tinplate

- Printing Tinplate

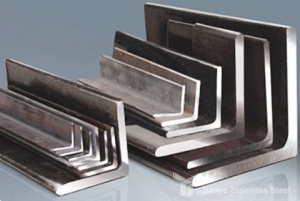

- Aisi 4140 Alloy Steel Bar

- Aisi 4340 Alloy Steel Bar

- Sae 1045 Carbon Steel Bar

- Sae 1020 Carbon Steel Bar

- S355jr Carbon Steel Bar

- S355jr Carbon Steel Bar

- Aisi 8620 Alloy Steel Bar

- Aisi 5120 Alloy Steel Bar

- Aisi 5140 Alloy Steel Bar

- 304l Cold Rolled Stainless Steel Coil

- View All

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)