Acid proof Bricks Lining

Acid proof Bricks Lining

Uma Clay Chem specialized in single source responsibility service, contractors including desing, selectonh of lining materials,lining, coating and Acid proof Bricks/Tiles lining.Acid proof Bricks installations provide protection against mechanical abuse and elevated temperature a complete. Line of acid proof bricks flooring systems for protection of plant floors that are subject to corrosion, wear of chemical spills are also available.Uma Clay Chem has been active in installations of acid proof bricks in many location in Gujarat, Rajastan and M.P . We have the ability to provide our services to any location throughout the Gujarat, Rajastan and M.p.It has taken yearʹs (14) to attain this level of expertise and we would be proud to be service to you, in an industry where quality, consistency and dependability are our greatest assets.

•CONCRETE SUBSTRATE

The concrete substrate should be sound, clean, dry andfree from any contamination. Proper slope be maintained in all areas.

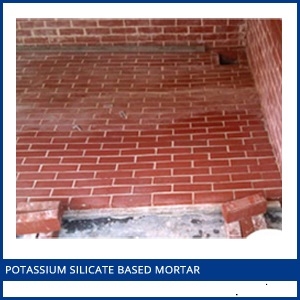

•BEDDING MORTAR

The bedding mortar in the direct lining system provides adhesion of brick or tiles to the substrate and also acts as a protective layer beneath the brick or tiles.Bedding mortar is a smooth soreading epoxy mortar, resistant to dilute acids, alkalis and some solvents. It is applied at a thickness of 6 mm to properly prepared substrate using anotched or straight trowel.

•JOINTING MORTAR

Uma Clay Chem can provide a suitable mortar for joints filling dependent upon chemical exposure. This mortar may be installed using the Bricklayerʹs method or Tileslayerʹs method.

•BRICK/TILE

Bricks or tiles selection is determined by the service conditions of area. 10mm to 25mm thick tile or 37mm and 75 mm thick brick are typically used. For a more attractive appearance the face of the brick or tile should be protected with wax to prevent the mortar adhering to the surface. Steam cleaning or hot water then removes this wax

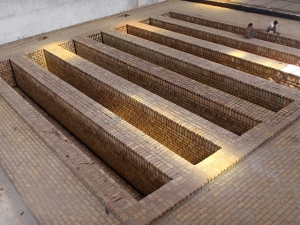

This type of lining work is done on RCC storage tanks and can be done in following step.

• Anti corrosive bitumen primer coating.

• Mastic lining (5mm to 6mm ).

•Acid proof 230X114X37 mm-Bribks lining.

• Pointing with Acia & Alkali & Solvent resisting Furane or CNSL.