Hydraulic Presses

Hydraulic Presses

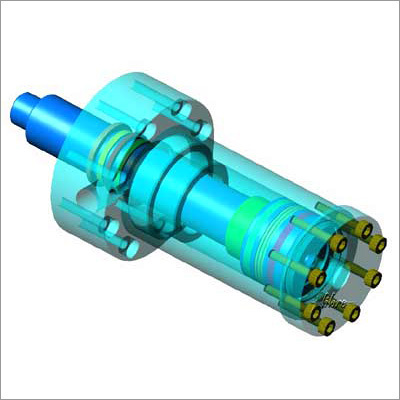

Hydraulic presses provide fast approach slow pressing & fast return speeds. The change in speed can be manually preset to take place at any point of the stroke with the help of limit switches / proximity switches or rotary encoders & potentiometers.

The frame is fabricated by ultrasonically tested quality profiles & plates of suitable thickness to with stand the load & longer life of the press. The frames are stress-relieved by ultrasonic virbrators.

Maximum frame rigidity is achieved through computer aided frame design & finite element analysis.

Extra long, precision machined & hardened guides to face slides offer exceptional accuracy & alignment which further reduced to wear.

In blanking or punching, hydraulic presses a damping system can be fitted. This effectively reduces breakthrough noise & tool wear normally generated by such operations.

The low noise hydraulic power pack unit is designed as per international practices & assembled with internationally reputed make components. The presses are designed as per ISI guidelines, hence standard seals, bushes are used.

Precise machining of the structural members is done after normalising to get the required accuracies like parallelism between platen & bed & right angularity between bed & the moving platen

Send Enquiry