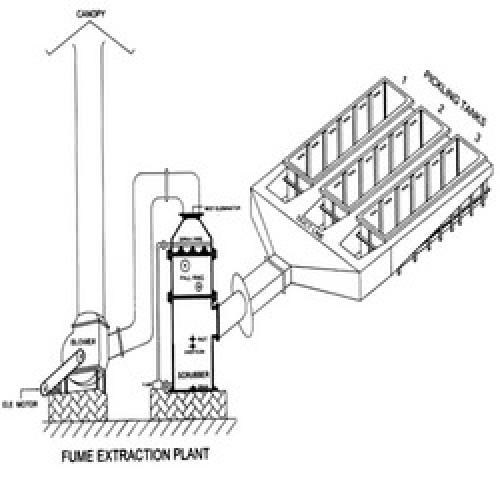

Fume Extraction System

Fume Extraction System

The most important basis for calculations are the determination of the exaust air volume and the dependence of the pre-treatment plant. All the calculations are performed by program modules developed by us. Effective scrubbing and guaranteed compliance with emission limits can only be achieved through an individually designed fume extraction plant optimized on the particular application. Our Fume Extraction plants can be used not only in encapsulated pre-treatment plants but also for lateral suction channels on pickling tanks. Performance of our Fume Extraction plants is as per emission regulations. We supplies Maximum Achievable Control Technology (MACT) in compliance to emission regulatory agency requirements. * It is incresingly recognised that for increased productivity and environment protecyion is important and vital role is played in manufacturing process. * Turn-key execution of system for extraction of corrosive fumes and gases. * Ensure hygienic working atmosphere * Committed to a cleaner environment * High separation efficiencies of 1 micron particulate and gaseous emissions are achievable. Customized process equipment for metal finishing industries. OUR FUME EXTRACTION SYSTEM AVAILABLE FOR * Hot-dip Galvanizing Plants * Pipe Pickling Plants * Stainless Steel Pickling Plants * Wire Pickling Lines * Electroplating /Anodising Plants * Metal Finishing Industries * Surface Treatment Plants ADVANTAGES * Clean Working Area (surrounding) Good housekeeping. * Ensures hygienic working atmosphere. * High employess\\\\\\\' acceptance. * Increased productivity. * Low production cost. * Stop corrosion of crane & roof structure. * Better safety. * Fumes are condensed & recycled. * Optimising material use. * Reducing waste disposal cost. * As per Emission regulations.

Send Enquiry