Graphite Rolls

Graphite Rolls

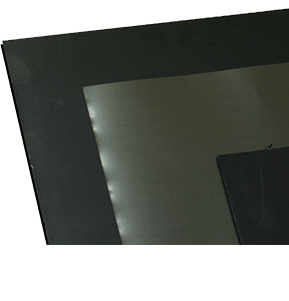

Pure Flexible Graphite rolls are produced from chemically pure natural flakes of graphite with high carbon content by expansion of flakes under high temperature. Finally, they are calendared maintaining desired thickness. Expanded pure natural Graphite is inert to wide range of chemicals, thermos table at high and cryogenic temperatures and bears high radiation resistance coupled with excellent thermal conductivity. It is highly compressible, has very low creep, moldable to complex shapes & conformable to all surface geometries. It has high surface area and excellent lubricity. Thes properties make it an ideal fluid sealing material as raw material for making Gland Packing Rings and Flange Gaskets.

These versatile properties of Expert Engineering Graphite rolls can be used to manufacture Die Molded Rings, Pressure Seal Rings, Cut Gaskets,Spiral Wound Gaskets, Heat Conductive products, Fuel Cell Components and many other applications.

Product Specifications

Rolls Size : 1000 mm width x 0.2 mm,0.38 mm, 0.5 mm,0.6 mm,0.76 mm,1.0 mm, 1.5 mm Thick

Roll Length : 30 M, 50 M

Density : 0.7 gms/cc and 1.0 gms/cc

Working Temperature

In Oxidizing Atmosphere : - 240 to 450 °C

In Steam : - 240 to 650 °C

In Non Oxidizing Atmosphere : - 240 to 3000 °C

Pressure : Full Vacuum to 100 Bar.

Ph Range : 0 - 14

Technical Data

Carbon Content : 99.50 %

Ash Content : < 00.50 %

Tolerance of Density : 00.05 gms/cc

Tolerance of Thickness : 00.04 mm

Tensile Strength : > 04.50 ( MPa )

Compressibility : > 30 to 40 %

Recovery : > 10 %

Sulphur Content : < 500 ppm

Chloride Content : < 30 ppm

Stress Relaxation (Creep) : < 05.0 %

Ignition Loss : < 00.1 %

Stability Under Stress : (DIN 52913) 48 N/m2

ASME Code Factor “M value” : 2

ASME Code Factor “Y value” : 900 PSI Minimum.

Send Enquiry