PVC Pipes

PVC Pipes

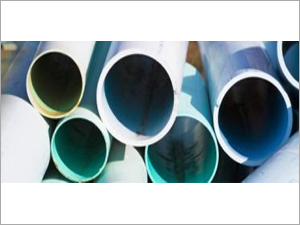

The polymers of High Density Polyethylene molecules are more opaque, stronger, harder and slightly heavier than Low Density Polyethylene. It is broadly composed of Carbon and Hydrogen. The other recycled polymeric ingredients of HDPE have made it a perfect component for pyrotechnics trade. Carbon black or UV- stabilizators are commonly used to make them resistant to weather and other reactive solvents.

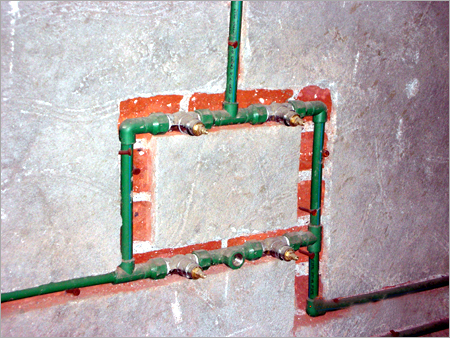

HDPE has a wide variety of industrial application in consumer products like, liquid distributor pipe, channels for domestic water supply, natural gas distributors, inner cable insulators, corrosion protectors for pipelines, plastic lumbers, sheds, ducts for telecom and other cell liners for homogeneous supply and extrusions. HDPE is readily available in various forms like sheet or tubes for fabrication.

Another most popular nonmetallic polymer used in pipeline industry is the Polyvinyl Chloride (PVC). Its resistance to internal stress and pressure is quite similar to HDPE. But while using in underground pressure piping, PVC shows its difference in terms of strength, price of material, installation cost, connection procedure and others. But as far as the application and usability is considered, each polyethylene material has a successful track record in terms of capacity and utility rating. In fact, innumerable industries and consumers are getting massive benefit from utterly growing usability of polyethylene products- starting from plastic bag to water tank or pipeline distributions in domestic or commercial purpose.

Readers with wider view on Polyethylene properties and usage are requested to discuss further posting their comments here.

Send Enquiry