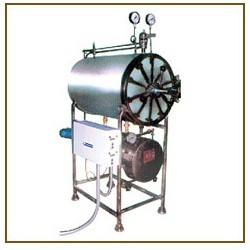

Horizontal Cylindrical

Horizontal Cylindrical

Our high efficiency steam sterilizers and robustly designed thermo dynamic sterilizers is equipped with an inner chamber. The sterilizer is fabricated using AISI 304/316 grade stainless steel for the inner chamber, with AISI 304 grade stainless steel for jacket, AISI 304 grade stainless steel for jacket and with AISI 304 grade Stainless Steel for the outer cover. The strong arc welded chamber and jacket ensure a leak proof construction. Our sterilizer is mounted on a corrosion resistant stand to ensure durability. Our sterilizer is based on the principle of downward displacement of air and assures minimum usage of water and steam for the sterilization. It is further available with steam strap for effective, economical removal of air and condensate from the chamber. This enhances to achieve sterilization temperature quicker. The option of a steam generator feed water pump assists uninterrupted operation. A powerful ejector fitted in the multi-port operating valve circulates air in the chamber for vacuum drying. With minimum heat loss the sterilizer enables a pleasant, comfortable, working environment. Our sterilizers are ISI marked which ensures optimum quality.

Centralized Control Point:

Multi-port valve control for the entire cycle of the operation

Permits two exhaust speed, fast & slow

Easy to read compound gauge for the chamber and pressure gauge for the jacket.

Smooth operation

Some of the salient features of our sterilizers are as follows:

Self locking safety door-cannot be opened while chamber is under pressure.

Gauge glass with automatic closing safety valve.

Heat resistant silicone door gasket

Pressure switch (on electric models) economic power consumption

Low water protection system, to protect the electric heaters

Temperature Gauge: Digital temp. indicators/controllers (optional)

Vacuum breakers, dryer

Safety value for the jacket and boiler

Hydraulically test to 2.5 times the designed working pressure.

Optional Features:

Heating Direct Steam Electric, LPG or Kerosene operated generators

Fully automatics operation through a micro stir process

Digital display temp and for a semi-automatic operation

Cycle with pre-vacuum option

Thermograph to record temperature and time

Double door type models

Stainless steel flush mounting

Blue water, vacuum leak detection tests for vials and ampules etc.

Carriages, trolleys, baskets etc. for easy movement of goods

Operation Direct Steam: 1.2 kg/ cm2 pressure OR 2.1 kg/ cm2 for High speed models Electricity: 3 phase, 440 V, 50 Hz AC supply.

Technical Specifications:

Model Chamber Ã

mm Chamber Depth

mm Chamber

Volume trs. steam generator

Capacity (litre/KW) Floor Space

(Width X Depth) Packed (Kg)

ASC-30HS 400 600 79 45/18 1130 x 1900 380

ASC-31HS 500 900 186 69/36 1175 x 2210 600

ASC-32 400 600 79 26/6 1130 x 1900 350

ASC-33 400 1100 145 44/9 1130 x 2275 550

ASC-35 500 900 186 44/9 1175 x 2210 575

ASC-36 500 1100 227 44/9 1175 x 2350 625

ASC-36 600 900 267 44/9 1230 x 2400 750

ASC-37 750 1100 511 80/18 1460 x 9090 900

Send Enquiry